Mud Gas Separator Suppliers An Essential Component in Drilling Operations

In the oil and gas industry, drilling operations are pivotal to extracting resources from beneath the earth\'s surface. One of the critical components of a safe and efficient drilling operation is the mud gas separator, which helps manage the influx of gas that can be encountered while drilling. A multitude of suppliers exists in the market, offering various types of mud gas separators designed to ensure safety and optimize drilling performance.

Mud gas separators serve a fundamental purpose they separate gases from drilling mud before the mud returns to the surface. During drilling, especially in high-pressure zones, gases can be inadvertently released. If not managed properly, these gases can pose significant risks, including blowouts, which can lead to catastrophic events on a drilling rig. This is where the role of mud gas separator suppliers becomes critical.

What are Mud Gas Separators?

Mud gas separators are designed to effectively remove free gas from the drilling mud before it is circulated back into the drilling system. These are typically used in conjunction with other well control equipment, such as blowout preventers (BOPs), to manage wellbore pressure and prevent potential hazards. The separators work by allowing the gas to rise and escape while the heavier mud particles settle and return to the circulation system.

The Importance of Choosing the Right Supplier

Selecting the right mud gas separator supplier is an essential part of the drilling operation. A reliable supplier will provide high-quality, durable equipment that meets the specific needs of the drilling site. Key considerations when choosing a supplier include

1. Experience and Reputation An established supplier with a proven track record in the industry is often preferable. Their experience can lead to insights and optimizations that newer companies may not provide.

2. Product Range Different drilling environments might require different types of separators, such as vertical or horizontal designs. A supplier with a diverse product range can cater to various operational needs and challenges.

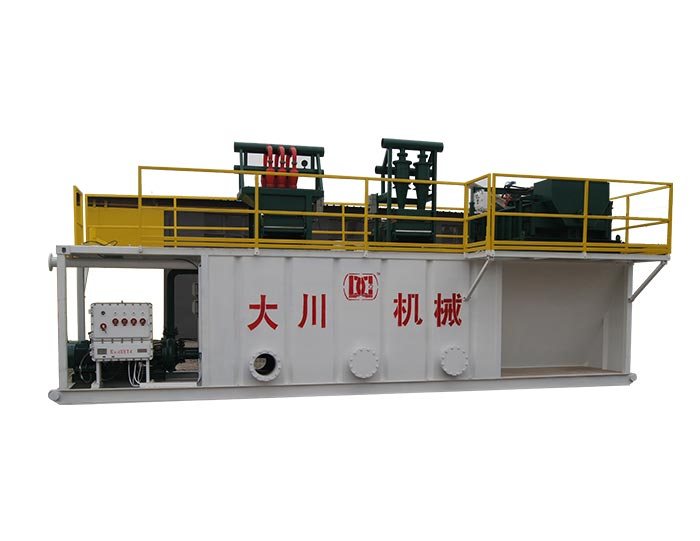

mud gas separator suppliers

3. Quality and Compliance The equipment must meet industry standards and safety regulations to function effectively. Suppliers should provide equipment that is certified and has undergone rigorous testing.

4. Technical Support and Training Investing in machinery is only part of the process; adequate training and support are crucial for personnel responsible for operating and maintaining the equipment. A good supplier should offer comprehensive after-sales support and training for the end-users.

5. Customization Every drilling operation is unique. Suppliers who can customize their equipment to fit specific needs provide added value. Custom solutions can help maximize performance and efficiency on-site.

Innovations in Mud Gas Separators

The demand for efficient and reliable mud gas separators has prompted many suppliers to innovate their designs. Modern separators incorporate advanced technologies aimed at improving gas separation efficiency and safety. Innovations may include enhanced materials that provide better durability and resistance to corrosion or systems integrated with real-time monitoring tools to track gas levels and performance metrics.

Additionally, automation in muddy gas separators is becoming increasingly prevalent. Automated systems help streamline operations, reducing the likelihood of human error and allowing operators to focus on more complex tasks. These improvements can lead to significant cost savings and enhanced safety for drilling crews.

Conclusion

Mud gas separator suppliers play an essential role in the oil and gas drilling industry. By providing innovative, reliable, and compliant equipment, these suppliers help ensure safer and more efficient drilling operations. As technological advancements continue, the collaboration between drilling companies and mud gas separator suppliers will be vital in addressing evolving challenges in the field. For drilling operators, choosing the right supplier can make a significant difference, impacting not only the bottom line but also the safety and success of their operations.

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump