In the realm of drilling operations, efficiency and safety are paramount. Among the myriad of technologies and equipment that facilitate these objectives, solid control equipment stands out as a cornerstone of modern drilling methodologies. This blog delves into the intricacies of solid control equipment, its indispensable role in drilling operations, the latest advancements, and the pivotal contributions of solid control companies in shaping the industry's future. Additionally, we'll explore the importance of control of leachate in landfills, which, although indirectly related, underscores the broader need for effective solid control in various industrial applications.

Understanding Solid Control Equipment

Solid control equipment is a suite of machinery and systems designed to manage and separate solids from drilling fluids during drilling operations. These fluids, which are circulated through the wellbore to cool the drill bit, lubricate the drill string, and carry cuttings to the surface, can quickly become laden with solids such as rock cuttings, sand, and other debris. Effective solid control ensures that these solids are removed efficiently, maintaining the fluid's properties and enhancing drilling performance.

Solid Control Equipment Used in Drilling Operations

Solid control equipment used in drilling operations encompasses a range of technologies tailored to specific stages of the drilling process. Here are some key components:

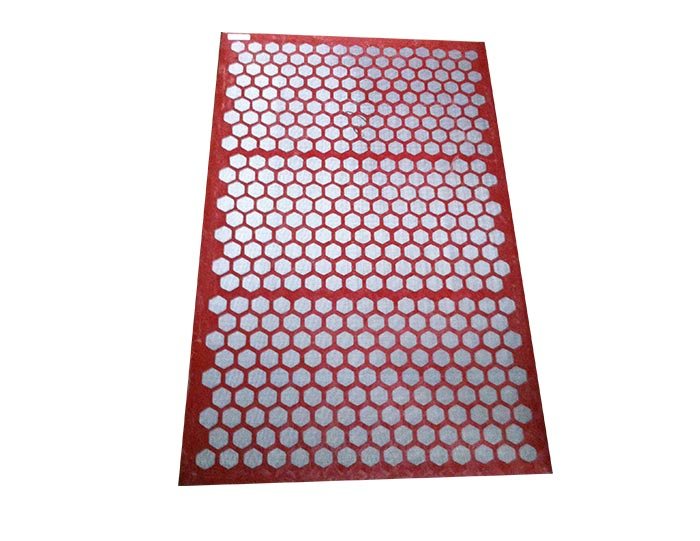

l Shale Shakers: These are the first line of defense in solid control. Shale shakers use vibrating screens to separate larger solids from the drilling fluid. Advances in screen technology, such as the incorporation of high-frequency and linear motion designs, have significantly improved separation efficiency.

l Mud Cleaners and Hydrocyclones: After the shale shakers, mud cleaners equipped with hydrocyclones further purify the drilling fluid by separating finer particles. These devices operate on the principle of centrifugal force, effectively removing particles down to microns in size.

l Decanter Centrifuges: For the most stringent solid control requirements, decanter centrifuges are utilized. These high-speed centrifuges separate particles as small as 2-5 microns, producing highly clarified drilling fluid.

l Desanders and Desilters: As their names imply, desanders and desilters are specifically designed to remove sand-sized particles and silt-sized particles, respectively. They often work in tandem with other solid control devices to ensure comprehensive fluid cleaning.

l Degassers: While not traditionally considered solid control equipment, degassers play a crucial role in maintaining fluid quality by removing entrained gases, which can affect drilling fluid density and stability.

The Importance of Solid Control

Effective solid control is critical for several reasons:

l Enhanced Drilling Efficiency: Clean drilling fluid flows more smoothly through the system, reducing friction and wear on equipment. This leads to longer tool life and less downtime.

l Improved Drilling Fluid Performance: Maintaining drilling fluid properties, such as viscosity and density, is vital for hole stability and cuttings transport. Solid control ensures that these properties are optimized.

l Environmental Compliance: Proper solid control minimizes the environmental footprint of drilling operations. Cleaner fluids mean reduced waste disposal challenges and lower potential for contamination.

l Cost Savings: Efficient solid control leads to reduced consumption of drilling fluids and chemicals, as well as decreased maintenance and repair costs.

Advances in Solid Control Technology

Recent advancements in solid control technology have focused on enhancing separation efficiency, reducing energy consumption, and integrating automation and data analytics. For instance, the adoption of IoT (Internet of Things) and AI (Artificial Intelligence) technologies allows for real-time monitoring and optimization of solid control processes. Predictive maintenance algorithms can anticipate equipment failures before they occur, minimizing disruptions and enhancing safety.

Moreover, the development of more durable and wear-resistant materials has improved the longevity and performance of solid control equipment. Innovations in screen media and centrifuge designs have led to finer particle separation and higher throughput capacities.

Control of Leachate in Landfills: A Related Perspective

While solid control in drilling operations is primarily concerned with managing solids in drilling fluids, the principle of controlling contaminants extends to other industrial applications, such as control of leachate in landfills. Leachate, the liquid that collects at the bottom of landfills from the decomposition of waste, contains a variety of pollutants that must be managed effectively to prevent environmental contamination.

Solid control techniques, albeit adapted and scaled appropriately, can inspire solutions for leachate management. For example, the use of separation technologies similar to those in drilling fluid systems can help treat and purify leachate before it is released into the environment. Advanced filtration and centrifuge systems can remove suspended solids, heavy metals, and organic pollutants, significantly reducing leachate's environmental impact.

Cross-pollination of ideas and technologies between solid control in drilling and leachate management in landfills underscores the interconnectedness of industrial challenges and the importance of innovative thinking in developing sustainable solutions.

In conclusion, solid control equipment is indispensable in modern drilling operations, ensuring efficient, safe, and environmentally compliant practices. The continuous advancements driven by solid control companies are crucial in meeting the evolving demands of the industry. As technology progresses, the integration of automation, data analytics, and durable materials will further enhance solid control capabilities.

Moreover, the broader principle of effective contaminant control, exemplified by solid control in drilling and leachate management in landfills, highlights the need for innovative solutions across various industrial sectors. By embracing these advancements, the drilling industry can continue to drive efficiency, safety, and sustainability, paving the way for a brighter, more resilient future.

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

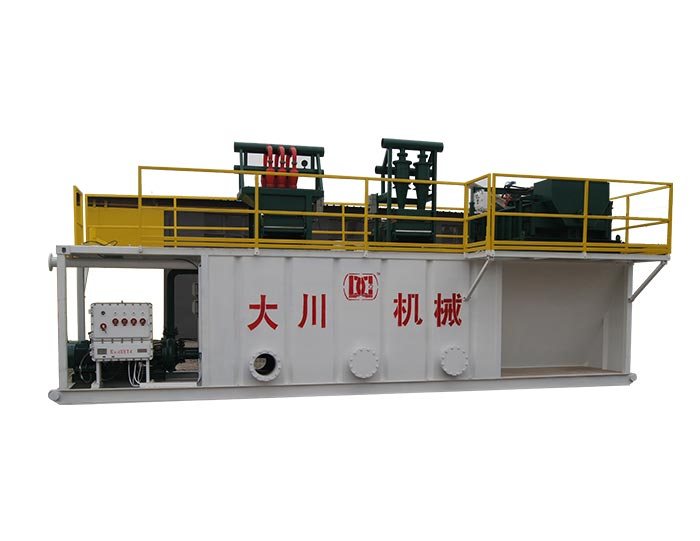

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump