shale shaker screen suppliers

Oct. 09, 2024

<p> A Comprehensive Guide to Shale Shaker Screen Suppliers</p><br>

<p>Shale shaker screens are essential components in the oil and gas industry, primarily used in the drilling process to separate the drilling fluid from the cuttings generated during the drilling operation. The efficiency and effectiveness of the shale shaker directly influence the overall drilling performance, making the quality of the screens a critical factor. This article aims to shed light on the various suppliers of shale shaker screens, highlighting their importance and the factors to consider when selecting a supplier.</p><br>

<p> Understanding Shale Shaker Screens</p><br>

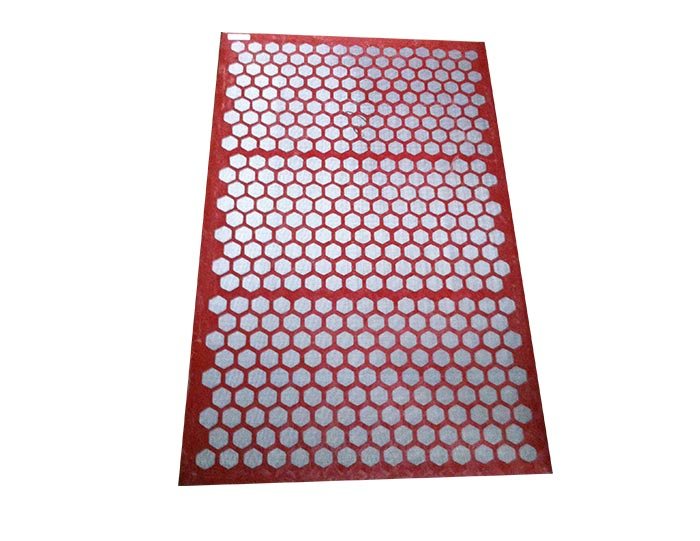

<p>Shale shaker screens are fabricated from various materials, typically including steel or composite materials that provide the necessary strength and durability. These screens come in different mesh sizes and configurations, tailored to meet specific drilling conditions and requirements. The primary function of these screens is to allow fluids to pass through while retaining solid particles, thus ensuring a clean drilling process.</p><br>

<p> Importance of Quality Suppliers</p><br>

<p>The performance of shale shaker screens significantly impacts drilling operations. High-quality screens can enhance the separation process, reduce fluid loss, and minimize the wear and tear on drilling equipment. Consequently, it is imperative to partner with reliable suppliers who offer superior products backed by industry experience and expertise.</p><br>

<a href=https://www.dcsolidscontrol.com/products><strong style="font-size:28px"><p> Top Considerations When Choosing a Supplier</p><br></strong></a>

<p>1. Product Variety A good supplier should offer a diverse range of shale shaker screens to cater to various drilling conditions and requirements. This includes different mesh sizes, materials, and screen types, allowing operators to select the best fit for their specific application.</p><br>

<p>2. Quality Assurance It\'s crucial to evaluate the quality of the products offered by the supplier. Look for manufacturers that comply with industry standards and conduct rigorous testing procedures. Certifications such as ISO 9001 can serve as indicators of quality management systems in place.</p><br><a href=https://www.dcsolidscontrol.com/products><strong style="font-size:28px">shale shaker screen suppliers</strong></a><br><br><img src="https://www.dcsolidscontrol.com/data/upload/20180130/5a701766a3a9f.JPG" alt="shale shaker screen suppliers" style="margin:0 auto;display:flex;justify-content:center;width: 50%;height: 50%;"><br>

<p>3. Custom Solutions Drilling operations can vary widely, so suppliers that provide customized solutions based on specific needs are often preferred. This could include designing screens tailored to unique operational challenges or suggesting modifications for improved performance.</p><br>

<p>4. Technical Support A reputable supplier should offer extensive technical support and guidance. This includes assistance with screen selection, installation, and troubleshooting, ensuring that clients can maximize the performance of their shale shakers.</p><br>

<p>5. Pricing and Value While price is an important factor, it shouldn’t be the sole criterion for selecting a supplier. Evaluate the overall value offered, including product quality, customer service, and after-sales support.</p><br>

<p>6. Reputation and Experience Researching a supplier\'s reputation within the industry can provide insights into their reliability. Long-established suppliers with a history of positive customer feedback tend to have proven track records.</p><br>

<p>7. Lead Times and Availability The efficiency of drilling operations can be adversely affected by delays in obtaining necessary equipment. Suppliers who can promise fast lead times and have stock readily available can mitigate these risks.</p><br>

<p> Leading Shale Shaker Screen Suppliers</p><br>

<p>Several suppliers have established themselves as leaders in the shale shaker screen market. Companies like Derrick Equipment Company and Swaco (a Schlumberger company) are well-regarded for their innovation, quality products, and excellent customer service. Other notable suppliers include Aipu Solids Control and Elgin Separation Solutions, known for their comprehensive offerings and custom solutions.</p><br>

<p> Conclusion</p><br>

<p>Choosing the right shale shaker screen supplier is pivotal for optimizing drilling operations in the oil and gas sector. The interplay between product quality, supplier reliability, and service capabilities can dictate the success of a drilling project. By carefully evaluating potential suppliers based on the criteria mentioned, companies can better position themselves to meet the challenges of the industry while enhancing operational efficiency and cost-effectiveness. As the market continues to evolve, staying informed about supplier advancements and trends will further empower operators to make educated decisions in their equipment procurement strategies.</p><br>

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

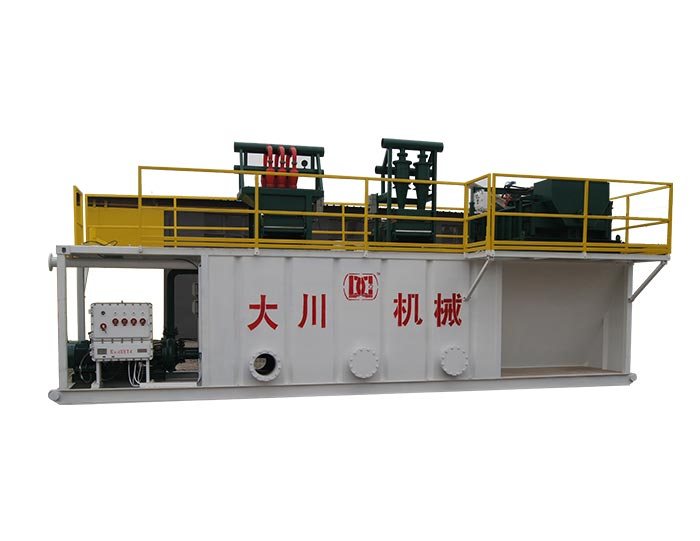

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump