shaker screens

Oct. 09, 2024

<p> Understanding Shaker Screens A Comprehensive Overview</p><br>

<p>Shaker screens are essential components in various industrial processes, particularly in the oil and gas sector, mining, and construction. These screens play a crucial role in the separation and filtration of materials, ensuring that the end products meet specific quality standards. This article explores the significance of shaker screens, their types, applications, and the technological advancements driving their efficiency.</p><br>

<p> What Are Shaker Screens?</p><br>

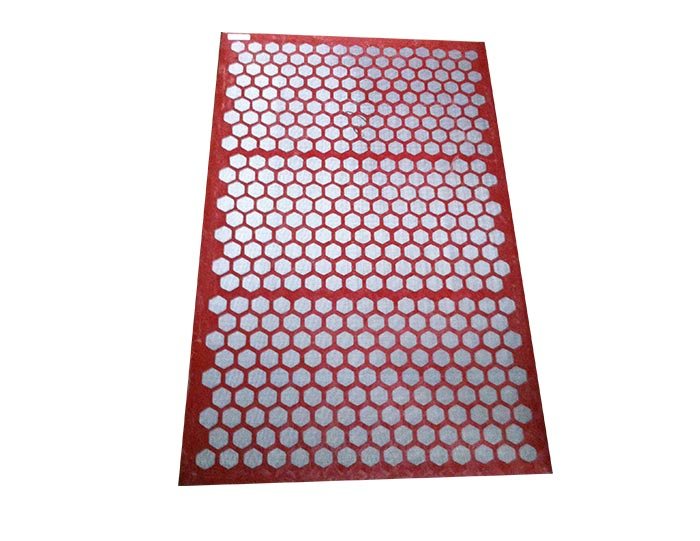

<p>Shaker screens are devices used to separate solid particles from liquids or other solids based on size, shape, and other physical properties. They are designed to be mounted on vibrating screens that use mechanical vibrations to facilitate the separation process. The screens themselves are typically made from wire mesh or perforated materials, allowing for varied mesh sizes to accommodate different types of materials.</p><br>

<p> Types of Shaker Screens</p><br>

<a href=https://www.dcsolidscontrol.com/products><strong style="font-size:28px"><p>There are several types of shaker screens, each with unique characteristics suited for specific applications</p><br></strong></a>

<p>1. Woven Wire Screens Made from metal wires that are tightly woven together, these screens are highly durable and capable of separating fine materials. They are often used in the mineral processing industry.</p><br>

<p>2. Polyurethane Screens These screens are made from flexible materials that offer excellent wear resistance and are suitable for high-impact applications. Their open area can be optimally designed, allowing for effective screening even with fine particles.</p><br>

<p>3. Composite Screens Combining the benefits of both woven wire and polyurethane, composite screens provide enhanced durability and flexibility. They are suitable for a variety of environments and operational conditions.</p><br><a href=https://www.dcsolidscontrol.com/products><strong style="font-size:28px">shaker screens</strong></a><br><br><img src="https://www.dcsolidscontrol.com/data/upload/20180130/5a701acb3e985.JPG" alt="shaker screens" style="margin:0 auto;display:flex;justify-content:center;width: 50%;height: 50%;"><br>

<p>4. Flip-Flow Screens These are designed for sticky and moist materials and use a unique bouncing mechanism to keep materials in motion, preventing clogging and ensuring continuous flow.</p><br>

<p> Applications of Shaker Screens</p><br>

<p>Shaker screens are used across a wide range of industries. In the oil and gas industry, they separate drilling fluids from cuttings, ensuring that the drilling process remains efficient and effective. In mining, they help classify materials before further processing, which is critical for resource extraction and management. In construction, shaker screens are employed for soil and aggregate separation, contributing to overall construction efficiency.</p><br>

<p>Moreover, shaker screens find applications in wastewater treatment facilities, where they help remove solids from liquids, ensuring cleaner and more environmentally-friendly discharge. Their ability to function under varying pressures and conditions makes them indispensable in these sectors.</p><br>

<p> Technological Advancements</p><br>

<p>The development of shaker screens has undergone significant advancements over the years. Innovations in materials, such as the use of high-strength alloys and composites, have dramatically increased the lifespan and effectiveness of screens. Additionally, the integration of digital technologies, including IoT (Internet of Things), allows for real-time monitoring and analysis of the separation process. Operators can optimize performance, predict maintenance needs, and reduce downtime.</p><br>

<p>Furthermore, advancements in design and manufacturing processes have led to custom solutions tailored to specific operational requirements. This level of customization ensures that industries can operate more efficiently and meet regulatory standards effectively.</p><br>

<p> Conclusion</p><br>

<p>Shaker screens are vital tools in separating and filtering materials in various industries. With their ability to improve efficiency, maintain product quality, and adapt to technological changes, they play a significant role in modern manufacturing and processing environments. As industries continue to evolve, the demand for advancements in shaker screen technology will likely increase, driving continual innovation and application across multiple sectors. Understanding their functionality and importance can help industries make informed decisions about equipment and techniques that enhance operational effectiveness.</p><br>

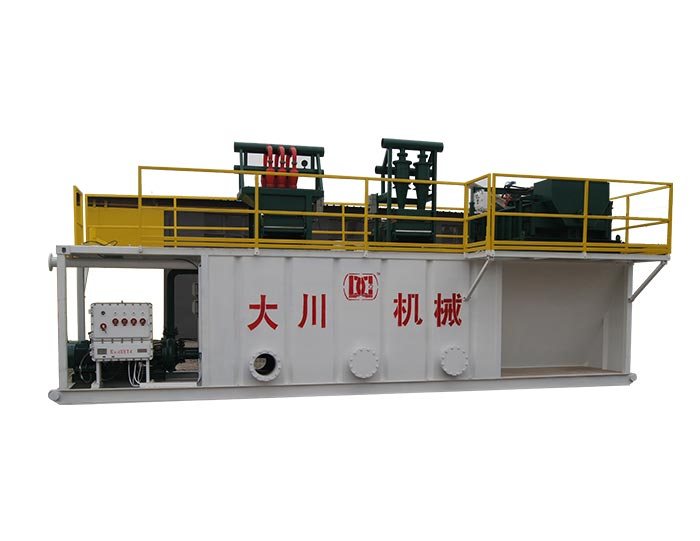

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump