In the vast landscape of industrial machinery, one device stands out for its simplicity, reliability, and versatility—the screw conveyor. These mechanical wonders have been integral to various material handling processes across numerous industries, from food processing to waste management. Today, we'll delve into the intricacies of screw conveyors, exploring their types, applications, safety considerations, and the unique advantages they offer. By the end of this blog, you'll have a comprehensive understanding of why screw conveyors are such a staple in industrial operations.

At its core, a screw conveyor, also known as an auger conveyor, consists of a rotating helical screw (auger) within a tube or trough. This screw rotates, propelling material along the length of the conveyor. The simplicity of this design belies its effectiveness in conveying a wide range of materials, from fine powders to bulky solids.

Types of Screw Conveyors

When discussing screw conveyor types, several variations exist to cater to different applications and material characteristics. Here are some key types:

l Standard Screw Conveyor: The most basic form, suitable for horizontal or slightly inclined conveying of a variety of materials.

l Double Screw Conveyor: As the name implies, this variant features two parallel screws within the same trough. It's ideal for handling high-capacity loads or materials prone to bridging (forming arches that hinder flow). The double screw conveyor ensures more consistent material movement and reduces the likelihood of clogging.

l Screw Feeder: A specialized type designed for precise metering and feeding of materials into processes. Screw feeders are often used in batching operations where accurate material quantities are crucial.

l Inclined Screw Feeder: Similar to a standard screw conveyor but installed at an angle. The inclined screw feeder is perfect for applications where vertical or near-vertical conveying is necessary, though it's generally limited to materials with good flowability and lower inclination angles to avoid material slippage.

l Screw Auger Conveyor: Essentially synonymous with a standard screw conveyor but emphasizes the auger's role in the conveying process. This term is often used interchangeably in industrial contexts.

Screw Conveyor Used For

The versatility of screw conveyors makes them indispensable in numerous industries:

l Food Processing: Used for conveying ingredients like flour, sugar, and grains in baking and confectionery operations. They're also ideal for handling food waste in processing plants.

l Chemical and Pharmaceutical: In these sectors, screw conveyors are employed for moving powders, granules, and small pellets. Their enclosed design minimizes dust exposure and cross-contamination risks.

l Waste Management: Essential for conveying waste materials like sludge, compost, and recyclables in waste treatment facilities and recycling plants.

l Mining and Aggregates: Used for transporting ores, sands, and gravels in mining operations and aggregate processing plants.

l Agriculture: Ideal for conveying fertilizers, grains, and animal feed in farming operations.

Screw Conveyor Safety

Despite their robustness, operating screw conveyors safely is paramount to prevent accidents and ensure operational efficiency. Here are some key safety considerations:

l Guarding: Ensure all moving parts are adequately guarded to prevent worker contact. This includes guarding the drive mechanisms, access points, and the conveyor's inlet and outlet.

l Lockout/Tagout Procedures: Implement strict lockout/tagout (LOTO) procedures during maintenance and repairs to prevent unexpected startup.

l Material Compatibility: Ensure the conveyor's materials (steel, stainless steel, etc.) are compatible with the conveyed material to avoid corrosion, contamination, or wear.

l Overload Protection: Equip conveyors with overload protection devices to prevent damage from excessive loads.

l Training: Provide comprehensive training to operators and maintenance personnel on safe operating procedures, emergency shutdown protocols, and hazard recognition.

Design and Customization of Screw Conveyors

Screw conveyors can be highly customized to suit specific application needs. Key design considerations include:

l Trough Material and Finish: Options range from mild steel to stainless steel, with various finishes to resist corrosion and wear.

l Screw Design: The pitch (distance between screw flights), diameter, and material of the screw can be tailored to optimize conveying efficiency for different materials.

l Drive Configurations: Choices include direct-drive, belt-drive, and gear-drive systems, each offering different performance characteristics and maintenance requirements.

l Inclination and Length: Conveyors can be designed for horizontal, inclined, or even vertical conveying, with lengths varying from a few feet to hundreds of feet.

Maintenance and Troubleshooting of Screw Conveyors

Regular maintenance is crucial for extending the lifespan and maintaining the efficiency of screw conveyors. Key maintenance tasks include:

l Lubrication: Regularly lubricate bearings, gears, and chains to reduce friction and wear.

l Inspection: Conduct regular inspections for signs of wear, corrosion, or damage. Pay particular attention to the screw flights, trough, and bearings.

l Cleaning: Keep the conveyor clean to prevent material buildup, which can lead to clogging and increased wear.

l Alignment: Ensure the conveyor is properly aligned to prevent vibrations and unnecessary wear on bearings and shafts.

Common troubleshooting issues include material bridging, screw wear, and bearing failures. Addressing these issues promptly can minimize downtime and operational disruptions.

In summary, screw conveyors are indispensable tools in the industrial material handling landscape. Their simplicity, versatility, and reliability make them ideal for conveying a wide range of materials across diverse industries. By understanding the different screw conveyor types, their applications, and the critical safety and maintenance considerations, businesses can harness their full potential. Whether you're looking to optimize an existing process or implement a new conveying system, screw conveyors offer a robust and efficient solution.

As technology advances, so too do the capabilities of screw conveyors. Innovations in material science, drive systems, and automation are continually pushing the boundaries of what these devices can achieve. Staying informed about these advancements can help businesses stay competitive and adapt to evolving market demands.

In conclusion, the screw conveyor is a testament to the power of simplicity and versatility in industrial design. Its ability to efficiently convey materials in a wide range of conditions and applications makes it a cornerstone of modern manufacturing. By embracing its potential and adhering to best practices in safety and maintenance, businesses can unlock its full value, driving operational efficiency and productivity.

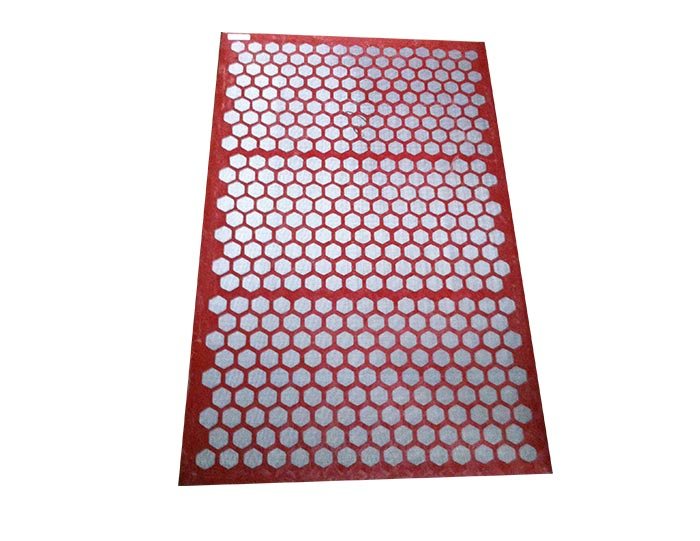

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

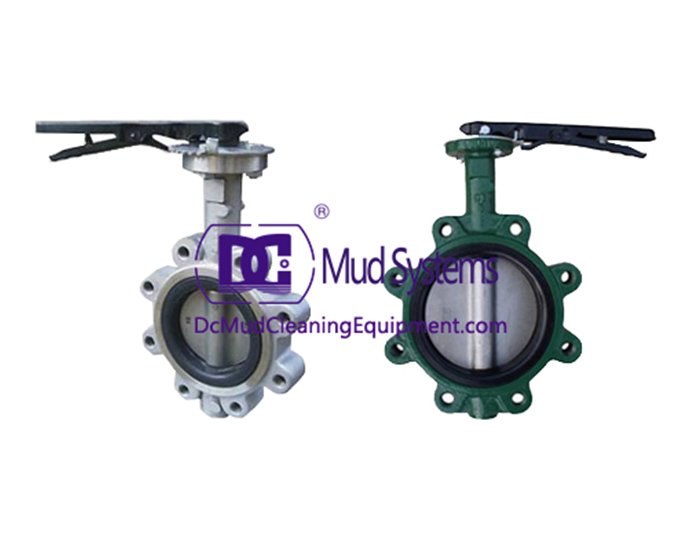

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

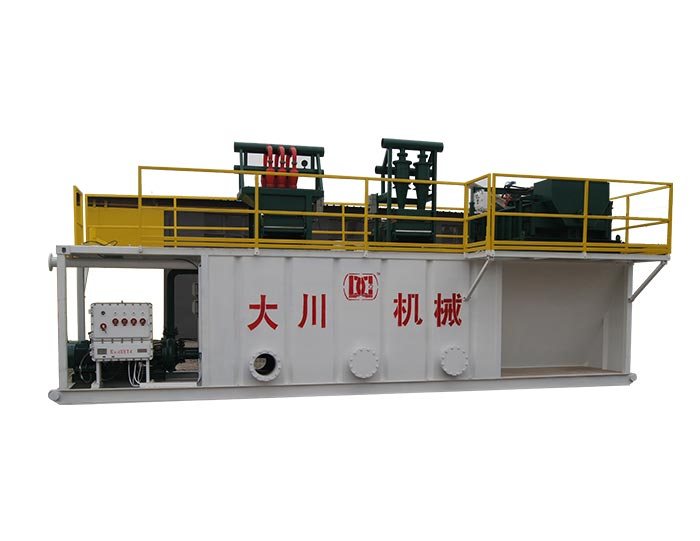

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump