mud systems for drilling

Oct. 09, 2024

<p> Mud Systems for Drilling An Essential Component of Oil and Gas Exploration</p><br>

<p>Drilling for oil and natural gas is a complex and challenging endeavor, where the selection and management of drilling fluids—often referred to as mud—is critical to the success and efficiency of the operation. The concept of mud systems in drilling encompasses a range of fluids used to facilitate the drilling process, stabilize the wellbore, and optimize overall drilling performance. Understanding the various types of mud systems and their functions is essential for anyone involved in the drilling industry.</p><br>

<p> The Role of Mud Systems</p><br>

<p>Mud systems are integral to the drilling process in several key ways. They serve to</p><br>

<p>1. Cool and Lubricate the Drill Bit As the drill bit penetrates various geological formations, it generates significant heat. A properly designed mud system helps to dissipate this heat and reduce friction, promoting efficient drilling and extending the lifespan of the drill bit.</p><br>

<p>2. Control Formation Pressure When drilling into underground reservoirs, maintaining wellbore stability is crucial. The mud system must exert sufficient hydrostatic pressure to counterbalance formation pressure, preventing blowouts or collapse of the wellbore.</p><br>

<p>3. Transport Cuttings As the drill bit breaks through rock, it generates cuttings that need to be removed from the wellbore. The mud system carries these cuttings to the surface, where they can be analyzed and disposed of properly.</p><br>

<p>4. Provide Wellbore Stability A well-balanced mud system helps to stabilize the walls of the wellbore by creating a filter cake, which reduces fluid loss into the formation and minimizes the risk of wellbore collapse.</p><br>

<p>5.<a href=https://www.dcsolidscontrol.com/products><strong style="font-size:28px"> Facilitate Cementing and Completion Operations After drilling, mud systems help prepare the well for cementing and completion by conditioning the mud properties and ensuring that the well is free from contaminants</strong></a>.</p><br>

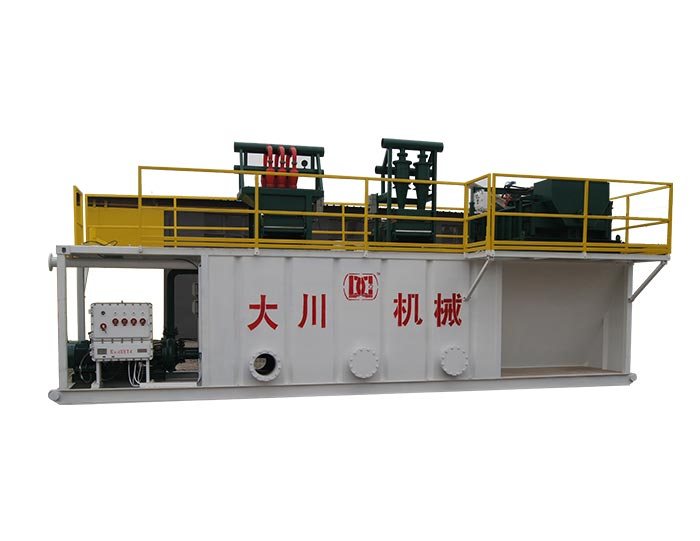

<p> Types of Mud Systems</p><br><a href=https://www.dcsolidscontrol.com/products><strong style="font-size:28px">mud systems for drilling</strong></a><br><br><img src="https://www.dcsolidscontrol.com/data/watermark/20180201/5a72a83db8075.jpg" alt="mud systems for drilling" style="margin:0 auto;display:flex;justify-content:center;width: 50%;height: 50%;"><br>

<p>There are various types of mud systems used in drilling operations, each tailored to specific geological conditions and operational requirements. The two primary categories of drilling fluids are</p><br>

<p>1. Water-Based Muds (WBM) These are the most common type of drilling fluids, consisting predominantly of water mixed with clay and other additives. Water-based muds are environmentally friendly, relatively inexpensive, and easy to handle. They provide good cooling and cleaning properties, making them suitable for a variety of drilling environments.</p><br>

<p>2. Oil-Based Muds (OBM) These muds are composed of oil as the base, often blended with emulsifiers, surfactants, and a variety of additives. Oil-based muds excel in high-temperature and high-pressure environments where water-based muds may falter. They provide better lubrication and minimize the invasion of water into the formation, making them ideal for drilling through shales and other sensitive layers.</p><br>

<p>3. Synthetic-Based Muds (SBM) A hybrid of water and oil-based systems, these fluids utilize synthetic oils to create a less toxic and more environmentally friendly alternative. They offer excellent performance in terms of stability and low filtrate loss, making them a preferred choice in sensitive drilling operations.</p><br>

<p> Selection Criteria for Mud Systems</p><br>

<p>Choosing the right mud system is crucial for ensuring drilling efficiency and safety. Key factors influencing the selection process include</p><br>

<p>- Formation Characteristics The composition of the rock and the presence of gas or water are critical in determining the appropriate mud system.

- Environmental Impact Regulations and environmental concerns may lead operators to opt for more eco-friendly mud systems, such as water-based or synthetic-based fluids.

- Operational Cost The cost of drilling fluids and their additives can significantly impact the overall budget of a drilling project. Operators need to balance performance with cost-effectiveness.

- Operational Depth and Pressure Deepwater drilling, for example, may necessitate the use of heavier muds to handle higher pressures, while shallow drilling might not require such measures.</p><br>

<p> Conclusion</p><br>

<p>Mud systems play a vital role in the success of drilling operations, serving as the backbone for efficient and safe drilling practices. As the oil and gas industry continues to evolve, innovations in mud technology and formulations will undoubtedly enhance drilling performance and reduce environmental impact. The importance of selecting the appropriate mud system cannot be overstated, as it directly affects not only the efficiency of the drilling operation but also the overall safety of the wellbore. Understanding the intricacies of mud systems is essential for professionals in the field and represents a critical component of modern drilling strategies.</p><br>

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump