In the dynamic world of oil and gas exploration, efficiency and reliability are paramount. Among the myriad of technologies and systems that drive this industry forward, the drilling mud cleaning system stands out as a cornerstone of modern drilling operations. This intricate network of mud cleaning equipment and machinery not only enhances the drilling process but also ensures the safety and sustainability of oil and gas extraction endeavors. Today, let's delve into the intricacies of this vital system, exploring its components, functions, and the transformative impact it has on the mud plant oil and gas sector.

Understanding the Drilling Mud Cleaning System

At its core, a drilling mud cleaning system is designed to maintain the quality and performance of drilling mud throughout the drilling process. Drilling mud serves multiple purposes, including lubricating the drill bit, cooling the drill string, and transporting cuttings to the surface. However, as drilling progresses, the mud becomes contaminated with cuttings, drilling fluids, and other impurities. This contamination can severely hinder the drilling process, leading to decreased efficiency, increased downtime, and potential safety hazards.

The mud cleaning system addresses these challenges by efficiently separating contaminants from the mud, thereby restoring its effectiveness. This system typically comprises a series of interconnected mud cleaning equipment and machines, each playing a crucial role in the cleaning process.

Key Components of a Mud Cleaning System

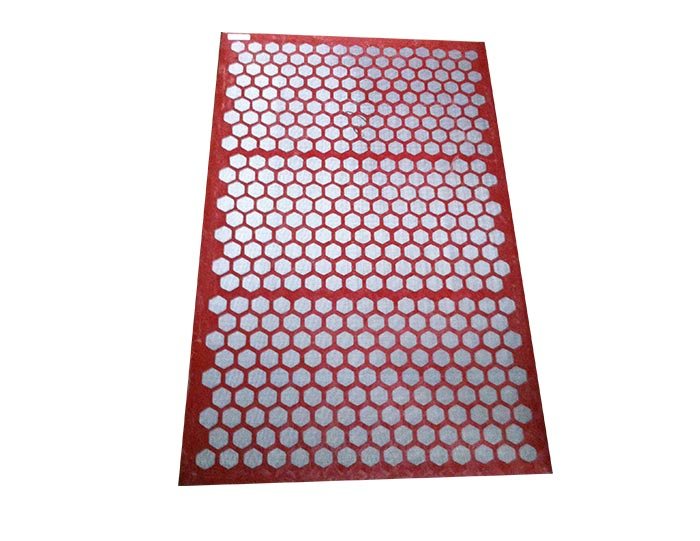

l Shale Shakers: These are the first line of defense in the mud cleaning process. Shale shakers use vibrating screens to separate larger particles, such as drill cuttings, from the mud. Advanced shale shakers often feature adjustable vibration frequencies and screen sizes to optimize separation efficiency based on the specific drilling conditions.

l Desanders and Desilters: After the initial separation by shale shakers, the mud passes through desanders and desilters. These devices utilize centrifugal force to separate finer particles, such as sand and silt, from the mud. Desanders are typically used to remove particles larger than 75 microns, while desilters target particles smaller than 44 microns.

l Mud Cleaners: Mud cleaners are a combination of shale shakers and hydrocyclones, designed to provide an additional level of cleaning. They are particularly effective in removing fine solids that may have escaped the initial separation stages.

l Centrifuges: For the most stringent cleaning requirements, centrifuges are employed. These high-speed devices separate particles as small as 2 microns from the mud, ensuring that only the purest mud is recirculated back into the drilling process.

l Mud Mixing and Conditioning Units: These units are responsible for maintaining the desired mud properties, such as viscosity and density. They often include agitators, heaters, and chemical injection systems to ensure that the mud remains within optimal operating parameters.

The Importance of Mud Cleaning Equipment

Each component of the mud cleaning system relies on specialized mud cleaning equipment to function effectively. The choice of equipment is critical, as it directly impacts the overall performance and efficiency of the drilling operation. For instance, high-quality shale shakers with durable screens and adjustable vibration settings can significantly reduce downtime and maintenance costs.

Similarly, advanced desanders and desilters equipped with high-efficiency hydrocyclones can improve particle separation accuracy, leading to cleaner mud and more efficient drilling. The integration of automated control systems and sensors further enhances the performance of these devices, allowing operators to monitor and adjust system parameters in real-time.

The Role of Mud Cleaning Machines in Oil and Gas Exploration

In the mud plant oil and gas sector, the efficiency of drilling operations is closely tied to the performance of the mud cleaning system. Clean mud ensures optimal drilling conditions, reducing the risk of equipment failure and drill bit wear. It also facilitates better hole stability and reduces the likelihood of stuck pipe incidents.

Moreover, efficient mud cleaning contributes to environmental sustainability by minimizing the volume of waste mud generated during drilling. This, in turn, reduces the cost and complexity of waste management and disposal operations.

Innovations in Mud Cleaning Technology

The oil and gas industry is constantly evolving, and so too are the technologies driving it forward. Recent innovations in mud cleaning equipment and machinery have focused on enhancing separation efficiency, reducing energy consumption, and improving automation and monitoring capabilities.

For example, the development of high-frequency shale shakers with advanced vibration control systems has led to more effective particle separation and longer screen life. Similarly, the integration of IoT and AI technologies in mud cleaning systems has enabled operators to monitor system performance remotely, predict maintenance needs, and optimize operational parameters in real-time.

Looking ahead, the future of mud cleaning systems is bright. Continued advancements in material science, automation, and data analytics will drive further improvements in separation efficiency, energy efficiency, and operational reliability.

One area of particular interest is the development of more sustainable mud cleaning solutions. This includes the use of biodegradable drilling muds and the implementation of closed-loop systems that minimize waste generation and environmental impact.

Additionally, as the oil and gas industry increasingly turns to deeper and more complex drilling environments, the demand for robust and versatile mud cleaning systems will continue to grow. Innovations in equipment design and system integration will be crucial in meeting these challenges and ensuring the ongoing success of drilling operations.

In conclusion, the drilling mud cleaning system is a vital component of modern oil and gas exploration. By efficiently separating contaminants from drilling mud, this system ensures optimal drilling conditions, reduces equipment wear, and minimizes environmental impact.

The continuous evolution of mud cleaning equipment and technology will play a pivotal role in shaping the future of the mud plant oil and gas sector. With advancements in automation, material science, and sustainability, we can expect even greater efficiency, reliability, and environmental performance from mud cleaning systems in the coming years.

As the industry continues to push the boundaries of drilling technology, the importance of maintaining clean and effective drilling mud cannot be overstated. By investing in advanced mud cleaning systems, oil and gas companies can enhance their operational efficiency, reduce costs, and contribute to a more sustainable future.

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

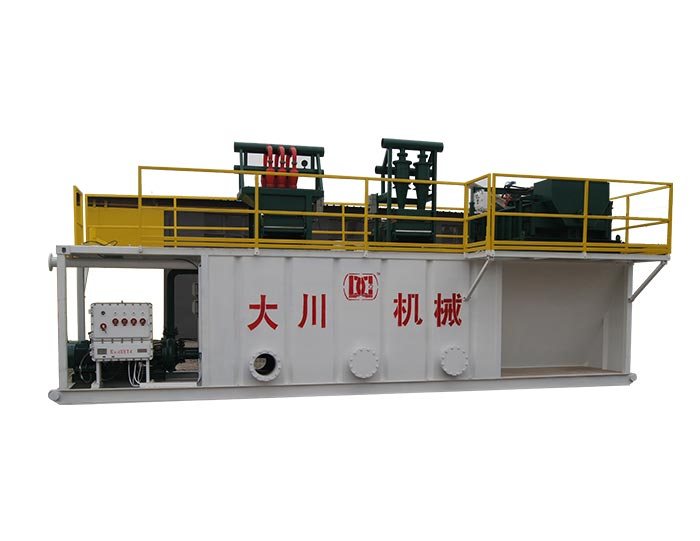

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump