High-Capacity Desander Enhancing Efficiency in Solid-Liquid Separation

In various industrial processes, particularly in oil and gas production, construction, and wastewater treatment, the separation of solids from liquids is crucial. One of the most effective tools for achieving this separation is the desander. Among the various types of desanders, high-capacity desanders have emerged as indispensable equipment for enhancing efficiency, reducing downtime, and improving environmental sustainability.

Understanding Desanders

Desanders are specialized devices designed to remove sand and other solid particles from liquids. By integrating a high-capacity design, these equipment systems can process larger volumes of fluid, making them especially beneficial for operations that generate significant amounts of solids. The principle behind a desander is relatively straightforward through the use of gravitational forces, centrifugal action, or a combination of both, solids are separated from the liquid phase.

Applications of High-Capacity Desanders

High-capacity desanders find applications across various industries

1. Oil and Gas Industry One of the primary domains for desanders is the oil and gas sector. When crude oil is extracted, it often contains sand and other contaminants that can damage equipment downstream. High-capacity desanders efficiently remove these solids, protecting pumps, compressors, and pipelines, thus prolonging their service life and reducing maintenance costs.

2. Construction and Mining In construction projects that involve the use of water, such as concrete mixing, high-capacity desanders help maintain clean water supplies by removing sediment and ensuring the quality of water used in various applications. Similarly, in mining operations, these devices are crucial for water reuse and maintaining environmental compliance.

3. Wastewater Treatment In municipal and industrial wastewater treatment facilities, high-capacity desanders play a vital role in managing the solids that settle out during the treatment process. By efficiently removing these particles, facilities can enhance their treatment efficiency and ensure the safe discharge of effluents into the environment.

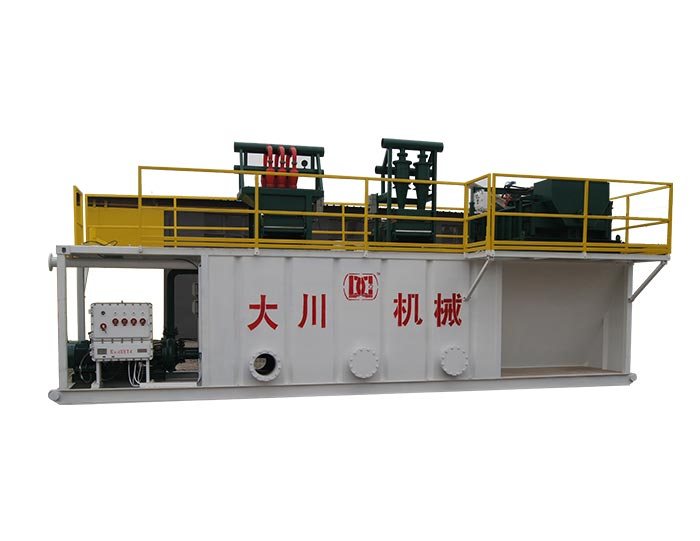

high-capacity desander

Benefits of High-Capacity Desanders

Investing in high-capacity desanders offers several benefits

- Increased Efficiency The capacity to handle larger volumes of fluid without compromising performance minimizes downtime. This is particularly advantageous in high-flow operations where needing to frequently stop for maintenance can lead to substantial productivity losses.

- Cost-Effectiveness By effectively managing solid waste, high-capacity desanders contribute to lower operational costs. Reductions in equipment wear and tear translate to fewer repairs and replacements, while optimized fluid management can lead to savings on water and processing resources.

- Environmental Compliance As industries face increasing regulatory pressures regarding waste management, utilizing high-capacity desanders can support compliance efforts. By minimizing the release of solids into the environment, companies can avoid fines and contribute positively to sustainability initiatives.

- Scalability High-capacity desanders are designed to adapt to varying operational scales. Whether it\'s a small construction site or a large industrial facility, these systems can be tailored to meet specific needs, providing flexibility as projects grow.

Conclusion

High-capacity desanders are an essential component of effective solid-liquid separation processes in various industries. With their ability to handle large volumes, these devices enhance operational efficiency, contribute to cost savings, and promote environmental sustainability. As industries continue to pursue innovative approaches to improve productivity and reduce waste, the role of high-capacity desanders will undoubtedly become increasingly significant. By integrating these systems into their operations, companies can achieve greater efficiency and ensure a cleaner, more sustainable future.

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump