hayes roll formers

Oct. 09, 2024

<p>Understanding Hayes Roll Formers A Comprehensive Overview</p><br>

<p>In the realm of manufacturing, the need for precision and efficiency is paramount, particularly in shaping and forming metal and other materials. Among the various technologies available, Hayes roll formers stand out for their ability to create complex shapes with remarkable accuracy. This article will explore the technology behind Hayes roll formers, their applications, and the advantages they bring to modern manufacturing.</p><br>

<p>What is a Roll Former?</p><br>

<p>A roll former is a machine that processes metal sheets or strips into desired shapes through a continuous bending operation. The metal is fed through a series of rollers that gradually alter its shape. Each pair of rollers is designed to achieve specific contours, providing an efficient way to mass-produce components. The roll forming process not only ensures uniformity but also minimizes waste, making it a preferred choice in many industries.</p><br>

<p>Hayes Roll Formers An Introduction</p><br>

<p>Hayes Manufacturing has established itself as a leader in roll forming technology, known for its commitment to quality and innovation. Hayes roll formers are designed to be versatile, accommodating a wide range of materials, including steel, aluminum, and other alloys. The versatility of these machines makes them suitable for several applications, from building materials to automotive parts.</p><br>

<a href=https://www.dcsolidscontrol.com/products><strong style="font-size:28px"><p>Key Features of Hayes Roll Formers</p><br></strong></a>

<p>1. Modular Design One of the standout features of Hayes roll formers is their modular design. This allows manufacturers to customize the machine according to their specific needs. Whether it\'s adjusting the roller configurations or integrating new technologies, the adaptability of Hayes roll formers helps optimize production processes.</p><br>

<p>2. Precision Engineering Accuracy is critical in roll forming, and Hayes has developed advanced engineering techniques to ensure high precision. This is achieved through tightly controlled tolerances in roller alignment and state-of-the-art monitoring systems that track the forming process in real-time.</p><br>

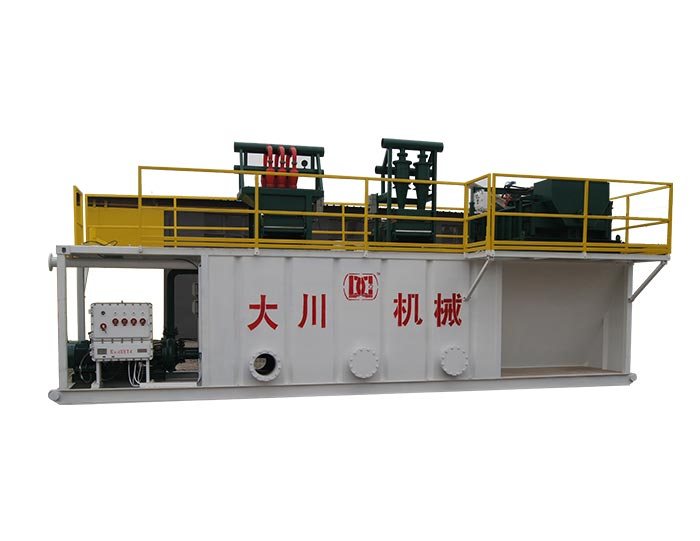

<p>3. Robust Construction The durability of Hayes roll formers is another critical advantage. Constructed with high-quality materials, these machines withstand the rigors of continuous operation, ensuring longevity and reducing maintenance costs. A strong chassis and reliable components contribute to consistent performance, making them a worthwhile investment.</p><br><a href=https://www.dcsolidscontrol.com/products><strong style="font-size:28px">hayes roll formers</strong></a><br><br><img src="https://www.dcsolidscontrol.com/data/watermark/20180201/5a727610dd1ed.jpg" alt="hayes roll formers" style="margin:0 auto;display:flex;justify-content:center;width: 50%;height: 50%;"><br>

<p>4. Energy Efficiency In today\'s manufacturing landscape, energy efficiency cannot be overlooked. Hayes roll formers are designed to minimize energy consumption while maximizing output. This not only reduces operational costs but also aligns with sustainable manufacturing practices.</p><br>

<p>Applications of Hayes Roll Formers</p><br>

<p>The versatility of Hayes roll formers means they can be found in numerous sectors. Some of the primary applications include</p><br>

<p>- Construction Used to manufacture frames, panels, and roofing components, Hayes roll formers contribute significantly to the building industry. They create lightweight yet durable products that meet the stringent demands of modern construction projects.</p><br>

<p>- Automotive Industry In automotive manufacturing, precision and weight savings are critical. Hayes roll formers produce parts like brackets, channels, and other structural components essential for vehicle assembly while adhering to safety regulations.</p><br>

<p>- HVAC Systems Heating, ventilation, and air conditioning systems rely on ductwork and fittings made through roll forming. The precision of Hayes roll formers ensures that these components fit together seamlessly, enhancing system efficiency.</p><br>

<p>- Furniture and Home Goods Custom shapes and components for furniture manufacturing also benefit from Hayes roll forming technology, allowing for innovative designs that meet consumer preferences.</p><br>

<p>Conclusion</p><br>

<p>Hayes roll formers represent a significant advancement in the manufacturing process, providing precision, adaptability, and efficiency across various industries. As manufacturers continue to seek ways to improve production capabilities, the technologies developed by Hayes will undoubtedly remain at the forefront. Their commitment to quality and innovation ensures that Hayes roll formers will be a vital component in the future of manufacturing, driving the industry towards more sustainable and effective practices.</p><br>

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump