Guard Rail Roll Forming Machine A Comprehensive Overview

In the realm of road safety, guard rails play a pivotal role in protecting vehicles from veering off roadways and ensuring the safety of drivers and passengers. At the heart of producing these vital structures is the guard rail roll forming machine. This piece of machinery is significant for manufacturers specializing in guard rails, offering a streamlined and efficient way to produce high-quality products for road safety applications.

Understanding Guard Rail Roll Forming Machines

A guard rail roll forming machine is a specialized type of equipment designed to convert raw materials, typically steel or aluminum strips, into finished guard rails through a continuous bending operation. The process involves feeding metal strips into the machine, where they undergo a series of stages, including cutting, bending, and forming, to achieve the desired profile.

These machines are characterized by their ability to produce various designs of guard rails, including W-beam rails, thrie-beam rails, and custom profiles as per the specifications of clients. By utilizing advanced technology, modern roll forming machines provide precision in dimensions, which is crucial for ensuring that the guard rails fit seamlessly into existing road infrastructures.

Benefits of Using Guard Rail Roll Forming Machines

1. High Efficiency Guard rail roll forming machines are designed for high production rates. They can create several meters of guard rail within a short period, enabling manufacturers to meet the growing demand for road safety products.

2. Cost-Effectiveness The automation involved in roll forming reduces labor costs while ensuring consistency in quality. With fewer manual interventions required, manufacturers can minimize operational expenses and enhance productivity.

3. Customization One of the standout features of these machines is their adaptability. Manufacturers can easily adjust the machine settings to create different sizes and types of guard rails, catering to unique customer specifications or regulatory requirements.

4. Durability and Quality Roll forming produces guard rails that have excellent structural integrity due to the continuous nature of the forming process. This ensures that the final products can withstand harsh environmental conditions and deliver long-lasting performance.

guard rail roll forming machine bulk

5. Innovation and Technology With advances in robotics and automation, the latest guard rail roll forming machines come equipped with smart technology. Features such as real-time monitoring and data analytics help operators optimize the production process, detect errors early, and maintain consistent quality control.

The Manufacturing Process

The manufacturing process of guard rails using roll forming machines involves several key steps

1. Material Preparation Raw materials, typically in coil form, are fed into the machine. These materials are selected based on the required specifications for strength and durability.

2. Feeding System The machine is equipped with a feeding mechanism that aligns the metal strips for uniform processing.

3. Roll Forming Process The metal strips undergo a series of rollers, each designed to incrementally bend the material into the desired shape. This continuous operation creates a uniform profile that meets design specifications.

4. Cutting and Finishing After forming, the guard rails are cut to the required lengths. Additional processes such as welding, punching holes for installation, and surface treatments such as galvanization may follow to enhance durability against corrosion.

5. Quality Inspection A thorough quality check is conducted to ensure that the finished products meet industry standards before they are packaged and shipped.

Conclusion

In conclusion, the guard rail roll forming machine is a crucial asset in the production of road safety features. Its efficiency, cost-effectiveness, and ability to produce high-quality and customizable guard rails mark its importance in the manufacturing industry. As roadways become increasingly populated, the demand for effective safety measures will continue to rise, making the role of guard rail roll forming machines ever more significant. Manufacturers investing in this technology can expect not only to meet regulatory demands but also to contribute positively to road safety across the globe.

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

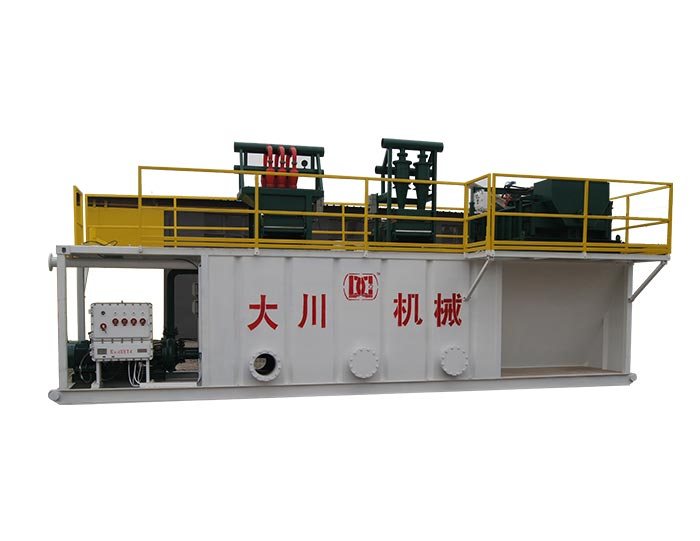

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump