In drilling operations, the equipment you use plays a crucial role in ensuring smooth and efficient processes. A mud hopper is one such piece of equipment that contributes significantly to the success of drilling activities. Whether it’s a mud mixer hopper or a mud mixing hopper venturi, each variation serves a distinct function, contributing to the overall efficiency of mud circulation and mixing in drilling operations.

Understanding the Mud Hopper and Its Role in Drilling

A mud hopper is an essential part of any drilling operation, designed to feed drilling fluids (mud) into the system. This device facilitates the efficient mixing and transportation of drilling mud to maintain the required viscosity and flow rate for optimal drilling performance. The mud hopper is responsible for mixing, adding, and displacing the drilling mud, ensuring that the system operates smoothly.

The Importance of the Mud Mixer Hopper for Smooth Operations

The mud mixer hopper plays a vital role in mixing and preparing drilling mud for optimal performance. It ensures that the mud is mixed consistently and is at the right density and viscosity to carry cuttings away from the drill bit. This function is especially important in ensuring that the wellbore is kept clean and the drilling process is efficient. Mud mixer hoppers are designed to work with various additives and ensure the proper blending of the mud components.

How the Mud Mixing Hopper Venturi Enhances Efficiency

One of the most advanced forms of mud hopper is the mud mixing hopper venturi. This device uses a venturi principle to draw and mix drilling fluid more efficiently. The mud mixing hopper venturi enhances the mixing process, increasing the speed and effectiveness with which the drilling mud is prepared and circulated. By creating a vacuum effect, the venturi helps in the rapid and uniform mixing of the components, resulting in a high-performance mud that is ideal for demanding drilling conditions.

Choosing the Right Mud Hopper for Your Needs

Selecting the right mud hopper for your operation depends on several factors, including the type of drilling being performed and the characteristics of the drilling fluid. Whether you're using a mud mixer hopper for standard operations or a mud mixing hopper venturi for more advanced, high-performance needs, the choice of equipment will directly affect the efficiency and success of the drilling operation. Proper maintenance and care are essential to keep the mud hopper functioning optimally, ensuring that the drilling process is not interrupted due to equipment failure.

Maximizing Performance with the Right Mud Hopper

Choosing the right mud hopper, whether it’s a mud mixer hopper or a mud mixing hopper venturi, can make a significant difference in the overall efficiency of drilling operations. Each type offers its own advantages in terms of mixing capability, flow rate, and performance under different drilling conditions. Investing in the right mud hopper ensures that your drilling operation will remain efficient, cost-effective, and smooth, making it an essential piece of equipment for any drilling project.

From the standard mud hopper to the high-efficiency mud mixer hopper and the advanced mud mixing hopper venturi, these tools help keep drilling operations running smoothly. Selecting the right one based on your specific needs can enhance productivity and reduce downtime, ensuring that your project stays on track.

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

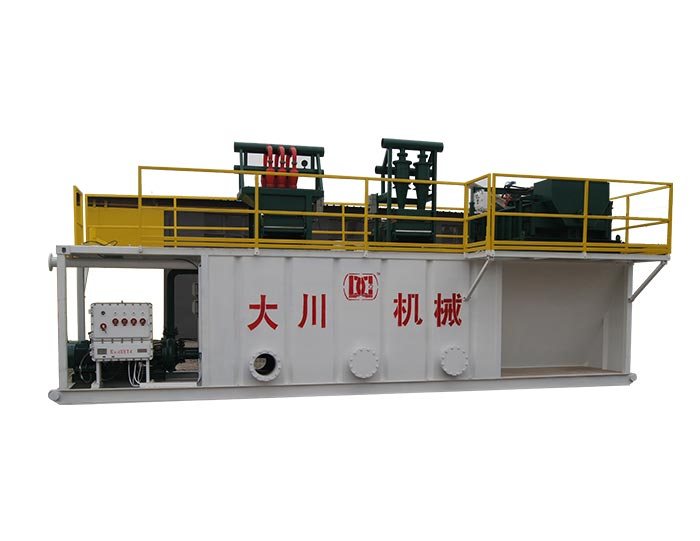

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump