In the oil and gas industry, drilling operations generate a significant amount of waste. This waste, often referred to as drilling waste, can pose significant environmental and operational challenges if not managed properly. Among the various types of drilling waste, drilling fluid waste management, drilling mud waste management, and overall drilling waste disposal are crucial areas of focus. This blog post will delve into the intricacies of drilling waste management, emphasizing the importance of effective strategies, services, and recycling options.

Drilling waste encompasses a wide range of materials, including but not limited to drilling muds, cuttings, and fluids used in the drilling process. Drilling muds are particularly significant because they play a vital role in the drilling process, lubricating the drill bit, cooling it, and carrying cuttings to the surface. However, once these muds have served their purpose, they become waste that requires careful management.

Drilling muds can be water-based, oil-based, or synthetic-based, and each type presents unique challenges for waste management. Water-based muds are generally easier to manage environmentally but can still contain contaminants such as heavy metals and chemicals. Oil-based and synthetic-based muds, on the other hand, can be more hazardous due to their hydrocarbon content.

The Need for Drilling Fluid Waste Management

Effective drilling fluid waste management is crucial for several reasons. Firstly, improper disposal of drilling fluids can lead to significant environmental contamination. These fluids can seep into soil and groundwater, causing long-term damage to ecosystems and human health. Secondly, poor management of drilling fluids can lead to operational inefficiencies. For instance, drilling muds that are not properly recycled or disposed of can lead to increased costs due to the need for new muds and the potential for equipment damage.

To address these challenges, companies in the oil and gas industry must adopt comprehensive drilling fluid waste management strategies. These strategies should include methods for reducing the volume of waste generated, recycling and reusing drilling fluids, and safely disposing of any remaining waste.

Drilling Mud Waste Management Techniques

Drilling mud waste management involves several techniques, including centrifugation, filtration, and thermal desorption. Centrifugation is a process that separates drilling muds into their constituent parts using centrifugal force. This can help recover valuable components of the mud, such as barite and bentonite, for reuse. Filtration, on the other hand, involves passing the mud through filters to remove solids and contaminants.

Thermal desorption is a more advanced technique that uses heat to separate hydrocarbons from drilling muds. This process can be particularly effective for managing oil-based and synthetic-based muds, as it allows for the recovery and reuse of the hydrocarbons. However, thermal desorption requires specialized equipment and can be energy-intensive, so it is generally used only when other methods are not feasible.

Drilling Waste Disposal Options

When recycling and reusing drilling muds is not possible or economically viable, companies must turn to drilling waste disposal options. These options include landfill disposal, injection wells, and deep-well disposal. Landfill disposal is the most straightforward method but can pose environmental risks if the waste is not properly contained and monitored. Injection wells and deep-well disposal involve injecting the waste into underground formations, which can be safer but also require careful geological assessments to ensure that the waste does not migrate and contaminate other formations.

The Role of Drilling Waste Management Services

Given the complexity and environmental sensitivity of drilling waste management, many companies choose to outsource these services to specialized providers. Drilling waste management services offer a range of solutions, from on-site waste management and recycling to transportation and disposal options. These services can help companies comply with environmental regulations, reduce operational costs, and minimize the environmental footprint of their drilling operations.

When selecting a drilling waste management service provider, companies should look for those with a strong track record of compliance, experience in the industry, and a commitment to sustainability. The provider should also offer a range of services to meet the specific needs of the company's drilling operations, including recycling and disposal options tailored to the type and volume of waste generated.

The Benefits of Drilling Waste Recycling

Recycling drilling waste offers numerous benefits, both environmentally and economically. By recycling drilling muds and other waste, companies can reduce the volume of waste that requires disposal, lowering their overall environmental footprint. Additionally, recycling can lead to significant cost savings by reducing the need for new drilling muds and other materials.

Moreover, recycling can help companies improve their operational efficiency. By reusing components of drilling muds, such as barite and bentonite, companies can reduce downtime and increase the productivity of their drilling operations. This can lead to increased profits and a competitive advantage in the oil and gas industry.

In conclusion, effective drilling waste management is crucial for the sustainability and profitability of oil and gas operations. By adopting comprehensive strategies for managing drilling fluids and muds, companies can minimize environmental risks, reduce operational costs, and improve their overall efficiency.

Outsourcing these services to specialized providers can be a particularly effective strategy, as it allows companies to leverage the expertise and resources of professionals dedicated to drilling waste management. Additionally, recycling drilling waste offers numerous benefits, both environmentally and economically, and should be a key component of any drilling waste management strategy.

As the oil and gas industry continues to evolve, the importance of effective drilling waste management will only increase. By embracing innovative techniques and services, companies can ensure that their drilling operations are both profitable and environmentally responsible. So, let's work together to manage our drilling waste effectively and contribute to a sustainable future for the oil and gas industry.

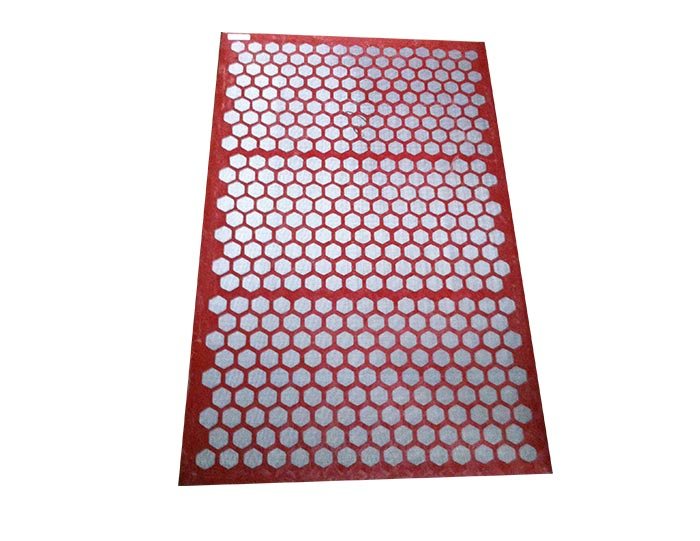

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

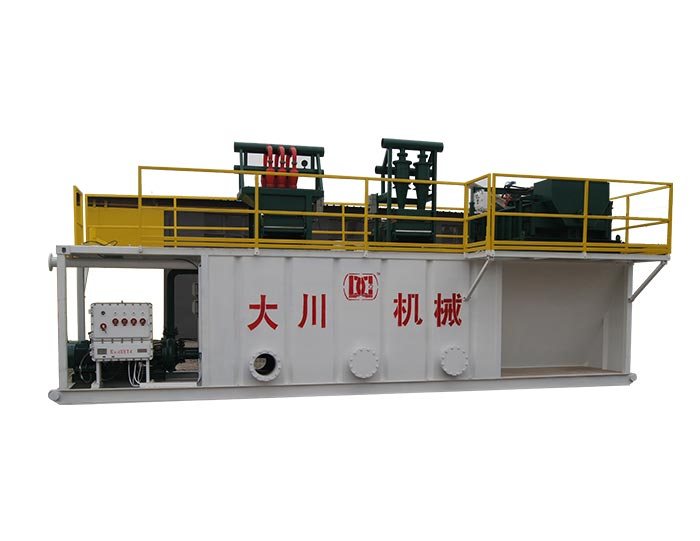

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump