bed frame laser pipe cutting machine

Oct. 09, 2024

<p> The Revolution of Bed Frame Manufacturing Laser Pipe Cutting Machines</p><br>

<p>In the ever-evolving world of manufacturing, the demand for precision, efficiency, and customization has led to significant advancements in machinery. One such innovation that has transformed the production of bed frames is the laser pipe cutting machine. This cutting-edge technology has not only streamlined the manufacturing process but also enhanced the quality and durability of the final products.</p><br>

<p> The Importance of Precision in Bed Frame Production</p><br>

<p>Bed frames serve as the foundation for a good night\'s sleep, providing not only support for mattresses but also contributing to the overall aesthetic of a bedroom. Given their importance, manufacturers must prioritize accuracy and quality in their construction. Traditional methods of cutting and shaping materials often resulted in inconsistencies and waste. However, laser cutting technology has changed the game by offering unparalleled precision.</p><br>

<p>Laser pipe cutting machines use high-powered lasers to cut through metal pipes with extreme accuracy. This technology allows manufacturers to create intricate designs and custom shapes without the errors associated with manual cutting methods. As a result, bed frames can be produced that are perfectly aligned and structurally sound, leading to better performance and longevity.</p><br>

<a href=https://www.dcsolidscontrol.com/products><strong style="font-size:28px"><p> Increased Efficiency and Productivity</p><br></strong></a>

<p>In addition to precision, laser pipe cutting machines significantly boost productivity. Traditional cutting methods often require multiple passes, adjustments, and manual handling, which can slow down the production process. In contrast, laser machines can execute complex cuts in a single operation, drastically reducing production time.</p><br>

<p>Manufacturers utilizing laser technology can meet high demand without compromising quality. Whether producing standard bed frames or customized options, laser cutting machines can accommodate various designs without the need for retooling or extended setup times. This flexibility allows companies to respond quickly to market trends and customer preferences, making them more competitive.</p><br>

<p> Cost-Effectiveness and Material Savings</p><br><a href=https://www.dcsolidscontrol.com/products><strong style="font-size:28px">bed frame laser pipe cutting machine</strong></a><br><br><img src="https://www.dcsolidscontrol.com/data/watermark/20180201/5a726d96e5853.jpg" alt="bed frame laser pipe cutting machine" style="margin:0 auto;display:flex;justify-content:center;width: 50%;height: 50%;"><br>

<p>Using laser pipe cutting machines not only improves speed and accuracy but also offers significant cost savings. The precision of laser cutting minimizes material waste, as the focused beam cuts through the metal with such accuracy that there are fewer lost scraps. This waste reduction translates into lower material costs and more sustainable manufacturing practices.</p><br>

<p>Furthermore, the durability of the products made with laser-cut components can lead to decreased warranty claims and returns, further benefiting manufacturers’ bottom lines. The investment in advanced laser technology can pay off quickly, as companies can reap the rewards of enhanced efficiency and reduced waste.</p><br>

<p> Customization and Design Flexibility</p><br>

<p>One of the most exciting aspects of laser pipe cutting technology is its ability to facilitate customization. Today\'s consumers are increasingly looking for personalized products that reflect their individual tastes and styles. Laser cutting machines enable manufacturers to easily create custom bed frames tailored to specific customer specifications.</p><br>

<p>Whether a customer desires a unique shape, size, or finish, laser cutting machines can quickly adapt to these requests, providing endless possibilities for design. This level of customization can enhance customer satisfaction and loyalty, as consumers feel they are receiving a product that is truly one-of-a-kind.</p><br>

<p> Environmental Considerations</p><br>

<p>As the manufacturing industry becomes more aware of its environmental impact, laser pipe cutting technology presents a greener alternative. The precision of laser cutting results in less energy consumption during production and decreased waste. Additionally, the longevity of laser-cut bed frames means that they are less likely to be discarded, contributing to a reduction in landfill waste.</p><br>

<p> Conclusion</p><br>

<p>The use of laser pipe cutting machines in bed frame manufacturing represents a significant advancement in technology, bringing numerous benefits to manufacturers and consumers alike. With increased precision, efficiency, and customization, these machines are set to revolutionize the industry. As consumers continue to seek high-quality, tailored products, manufacturers that embrace laser cutting technology will undoubtedly gain a competitive edge in the marketplace. In an age where quality and personalization are paramount, laser pipe cutting machines emerge as the perfect solution, ensuring that bed frames are not just functional, but also works of art that enhance the living space.</p><br>

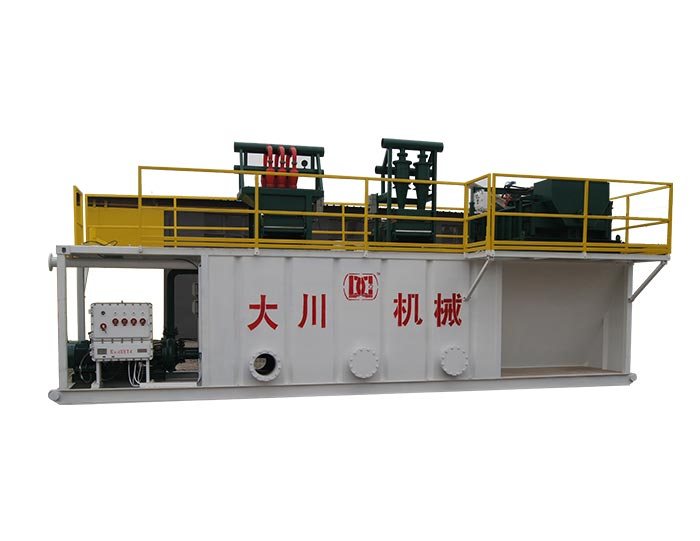

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump