Composite Floor Deck Forming Machinery An Overview

Composite floor deck forming machinery plays a crucial role in modern construction, particularly in the development of multi-story buildings, warehouses, and industrial facilities. This innovative equipment is designed to streamline the construction process, enhancing efficiency while ensuring structural integrity. In this article, we will delve into the workings of composite floor deck forming machinery, its benefits, and its impact on the construction industry.

What is Composite Floor Decking?

Composite floor decks are structural components that consist of a combination of concrete and steel. They are engineered to provide a robust flooring solution that supports both vertical and lateral loads in buildings. The primary purpose of composite decks is to act as a formwork for concrete while also serving as a permanent part of the flooring system.

In the context of composite floor decks, the steel component typically takes the form of a profiled deck, which is combined with a concrete topping to create a composite action. This combination allows for thinner slabs compared to traditional concrete-only systems, reducing the overall weight of the structure and potentially lowering construction material costs.

Role of Forming Machinery

Composite floor deck forming machinery refers to the specialized equipment used to manufacture the steel decking sheets and facilitate their installation

. This machinery is designed to create various profiles of decking, enabling construction companies to choose the most suitable design for their specific projects.

Modern forming machines are equipped with advanced technology that allows for higher precision, increased production speed, and reduced waste. They can produce decking with various depths, widths, and thicknesses, catering to different load requirements. Additionally, some machines are set up for automatic or semi-automatic operation, minimizing the need for manual labor and enhancing safety on the construction site.

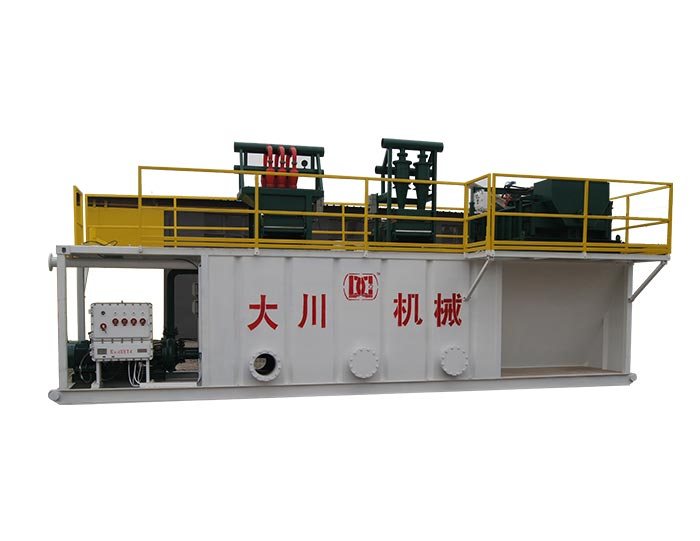

composite floor deck forming machinery

Key Benefits of Composite Floor Deck Forming Machinery

1. Increased Efficiency One of the most significant advantages of using composite floor deck forming machinery is the considerable increase in efficiency during the construction process. The ability to produce decking quickly and install it seamlessly reduces the time frame of projects, leading to faster completion times.

2. Cost-Effectiveness By using forming machinery, construction companies can lower material waste and labor costs. Automated processes enhance accuracy and reduce errors that typically lead to costly rework or delays. Moreover, the lightweight nature of composite decks can translate into savings on foundation costs.

3. Enhanced Structural Performance The precision of modern forming machinery ensures that each piece of decking is manufactured to exact specifications, resulting in superior structural performance. Properly manufactured and installed composite decks can enhance the resilience and longevity of buildings.

4. Environmental Benefits The efficiency of composite floor deck forming machinery contributes to a lower carbon footprint. Reduced material waste, coupled with the use of lighter-weight materials, results in a more sustainable approach to construction.

5. Versatility Composite deck forming machinery can accommodate various layouts and designs, making it a versatile choice for builders. Whether working on commercial, residential, or industrial projects, this machinery can adapt to different requirements and preferences.

Conclusion

Composite floor deck forming machinery has revolutionized the construction landscape, providing significant advancements in efficiency, cost-effectiveness, and structural integrity. As the demand for innovative construction techniques continues to grow, the role of this machinery in enabling faster, safer, and more sustainable building practices becomes increasingly vital. The ongoing development of technology in this field promises further enhancements, ensuring that composite floor decks remain a popular choice for diverse construction projects around the world. As industries strive for greater efficiency and sustainability, the importance of high-quality forming machinery cannot be underestimated in achieving these goals.

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump