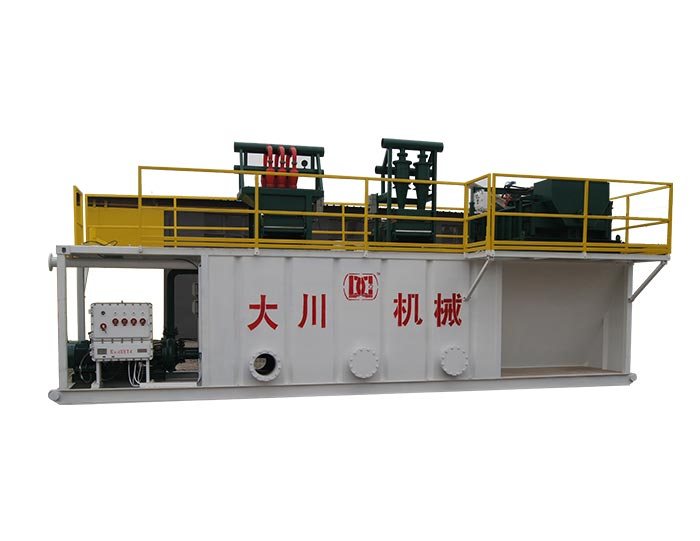

Introduction of Mud Cleaner

To overcome many of the limitations of current solids removal equipment, a combination (shale shaker, desander, desilter) equipment was developed for weighted mud. This solids control device, called a mud cleaner, removes most of the drilled solids while retaining most of the barite and the liquid phase of the mud, and plays an important role in a mud cleaning system. Unlike most barite recovery or solids removal equipment, which is typically used only after drilling solids reach undesired levels, mud cleaners are most effective when applied immediately after barite is added to the mud system, and are used continuously thereafter. . Continuous operation removes solids before they break down into silt or clay sizes, preventing drill bit solids from accumulating in the mud cleaning system. Mud Cleaner is the mud cleaning equipment combination of desander,desilter hydrocyclone and an underflow shale shaker.

Advantages of Mud Cleaner

(1)Compact structure, powerful function and small footprint area.

(2)The material of hydrocyclone use the wear-resistant special polyurethane.

(3)Underflow shaker equips the DC different model shale shakers.

(4)We can design and manufacture the different numbers of desander and desilter hydrocyclone for clients'requirements.

Mud Cleaner Parameters

| Model | DCQJ250 × 1/100 × 6 | DCQJ250 × 1/100 × 8 | DCQJ250 × 2/100 × 12 | DCQJ300 × 2/100 × 16 |

| Treating Capacity | 90m3/h

396GPM | 120m3/h

528GPM | 240m3/h

1056GPM | 300m3/h1320GPM |

| Separation Size | 15-75μm |

| Desander Cones | 10"(250) × 1 | 10"(250) × 1 | 10"(250) × 2 | 12"(300) × 2 |

| Desilter Cones | 4"(100) × 6 | 4"(100) × 8 | 4"(100) × 12 | 4"(100) × 16 |

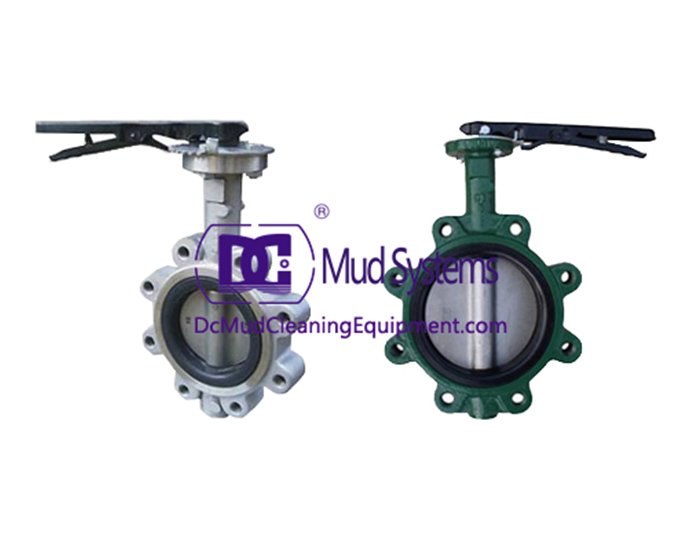

| Inlet Diameter | DN150 |

| Outlet Diameter | DN200 |

| Pressure | 0.25~0.40MPa |

| Matching Pump | DCSB5 × 4-12-22kW | DCSB6 × 5-12-30kW | DCSB8 × 6-13-55kW | DCSB8 × 6-13-55kW |

| Matching Shaker | Model | DCZS850-2K | DCZS700-3G | DCZS630-3K |

| Vibrating Model | Linear Motion |

| Motor Power | 2 × 1.5kW | 2 × 1.5kW | 2 × 1.5kW |

| Screen Qty | 2 panel | 3 panel | 3 panel |

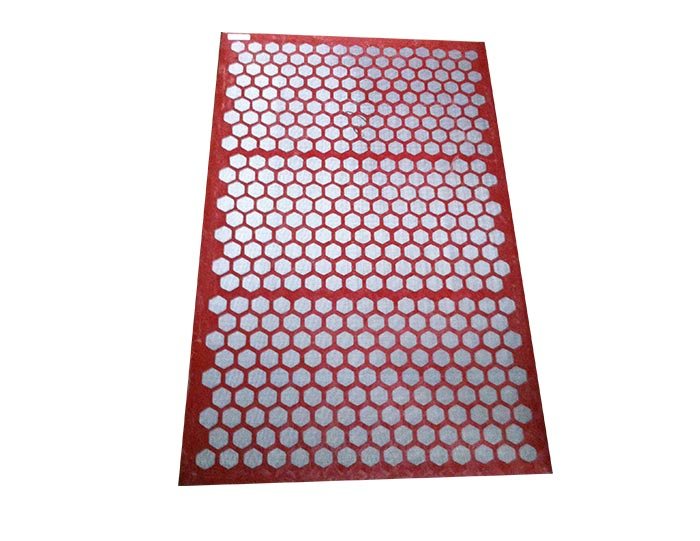

| Screen Specification | 850 × 1250mm × 2 panel,120~300mesh | 700 × 1050mm × 3 panel,120~300mesh | 630 × 1250mm × 3 panel,120~300mesh |

| Screen Area | 2.12m2 | 2.2 m2 | 2.36 m2 |

| Screen Type | Steel Frame | Hookstrip | Steel Frame |

| Electric Specs | 380V/50HZ or 460V/60HZ or Customized |

| EX Standard | Ex dⅡBT4 |

| Dimension | 2530 × 1750 × 2210 mm | 2530 × 1750 × 2210 mm | 2530 × 1750 × 2210 mm | 2530 × 1750 × 2210 mm |

|

| Weight | 1780kg | 2080kg | 2200kg | 2350kg |

|

| Remark | 1、4" Cones =10~20m3/h, 10" Cones =90~120m3/h ,12" Cones>120m3/h 2、The motor power of centrifugal pump choosed is according to drilling mud specific gravity 1.2g/cm3 |

Tangshan Dachuan Machinery specializes in the production and sales of mud cleaner and mud cleaning system. At the same time, we will also provide you with a complete system of after-sales service. You are welcome to ask us any questions at any time!

Location of Mud Cleaner in Drilling Fluid System

The Mud Cleaner is usually co-located with the desilter in the drilling fluid system. Typically, desilters or hydrocyclones are used for the unweighted portion of the borehole by diverting the underflow away from the mud tank. When adding weighting agents, barite or hematite to the system, the screen is placed on the mud cleaner shaker. The discarded solids from the hydrocyclone are sieved to discard most of the larger solids than the pyrite and the returned solids are smaller than the screen size of most of the liquid phase.

Another method has also been used to make mud cleaners using a major shale shaker, mostly on offshore drilling platforms. When multiple linear or balanced elliptical shakers are required to handle the flow in the upper part of the wellbore, fewer shakers can handle the flow after the wellbore size is reduced and the mud weight is increased. The rig was modified to mount up to 20 4-inch hydrocyclones above one main vibrator. The feed and overflow (light pulp) from the hydrocyclone are connected as usual. As usual, all the desilter underflow was discarded in the unweighted portion of the wellbore, while the shale shaker was sifting the drilling fluid from the flow line. Typically, this is the maximum flow expected when drilling. As the well gets deeper, the drilling fluid needs to be heavier, and the flow rate usually decreases. When barite comes in, the valve blocks the flow of streamlined drilling fluid to one of the main shale shakers. The desilter underflow is diverted to the shaker screen, making the shaker a mud cleaner.

How Does Solid Control Equipment Enhance Drilling Efficiency?

Solid control equipment plays a critical role in modern drilling operations by maintaining the quality and stability of drilling fluids. At Tangshan Dachuan Machinery Co., Ltd., our solid control equipment used in drilling operation is engineered to efficiently separate drilled solids from the drilling mud, ensuring optimal viscosity and fluid performance. A well-designed solid control system minimizes wear on drilling tools, prevents blockages, and reduces operational downtime. Central to our offerings is the mud cleaner, a highly efficient device that combines a shale shaker with desander and desilter units to remove the majority of drilled solids while retaining valuable barite and liquid phases. The drilling mud cleaner we provide integrates seamlessly into any solid control system, enhancing the effectiveness of your mud treatment process. By choosing our mud cleaner machine, customers benefit from a robust, high-performance solution that ensures consistent drilling efficiency and reduces maintenance costs. Tangshan Dachuan Machinery Co., Ltd. focuses on supplying the most advanced solid control equipment with rapid after-sales support, guaranteeing that your drilling operations stay productive and cost-effective.

Why Should Drilling Operations Invest in a Mud Cleaner Machine?

Investing in a mud cleaner machine significantly improves the sustainability and effectiveness of your drilling process. The solid control equipment used in drilling operation at Tangshan Dachuan Machinery Co., Ltd. ensures that drilled solids are separated efficiently, preventing unnecessary material waste. Our drilling mud cleaner integrates advanced separation technology, forming a complete solid control system that maintains the quality of drilling fluids over extended operations. With a proper mud cleaner drilling setup, barite recovery is maximized, fluid loss is minimized, and the environmental footprint of the drilling operation is reduced. The solid control benefits extend beyond cost efficiency; they also enhance the safety and reliability of the drilling site. Tangshan Dachuan Machinery Co., Ltd. specializes in providing mud cleaner and associated solid control equipment with high precision and durability, ensuring that operators achieve the highest return on investment while maintaining uninterrupted operations.

Can Mud Cleaner Drilling Reduce Operational Costs?

Yes. Implementing a mud cleaner drilling strategy with Tangshan Dachuan’s solid control equipment used in drilling operation can significantly reduce operational costs while improving overall efficiency. Our mud cleaner machine is specifically engineered to remove drilled solids efficiently while retaining essential drilling fluid components such as barite and the liquid phase, ensuring minimal mud loss and reducing the need for expensive additives. By maintaining the correct mud properties, our equipment allows drilling teams to sustain optimal viscosity and density, which prevents excessive wear on pumps, motors, and other drilling components. Integrating an advanced solid control system into your drilling operation ensures that every stage of solids removal—from shale shakers to desanders and desilters—is optimized for performance. The mud cleaner plays a critical role in this system, capturing fine solids that traditional equipment often misses, thereby extending the lifespan of drilling tools and minimizing downtime caused by equipment failure. Using Tangshan Dachuan’s solid control equipment helps operators avoid unexpected maintenance costs and improves the predictability of drilling schedules, which directly impacts overall project budgets. In addition to cost savings, our solid control equipment enhances operational safety and environmental responsibility. By efficiently managing drilled solids and retaining valuable mud components, the mud cleaner drilling process reduces the risk of formation damage and limits waste discharge, supporting compliance with modern environmental standards. Tangshan Dachuan Machinery Co., Ltd. ensures that all our solid control systems are designed with durability, reliability, and ease of maintenance in mind, allowing operators to focus on productive drilling rather than frequent equipment interventions.

Linear Motion Shale Shaker In Drilling Rig

Linear Motion Shale Shaker In Drilling Rig  Oilfield Mud Cleaner

Oilfield Mud Cleaner  Drilling Fluid Decanter Centrifuge

Drilling Fluid Decanter Centrifuge Drilling Mud Desander

Hydrocyclone Desilter

Centrifugal Pump/Centrifugal Mud Pump

Shear Pump

Jet Mud Mixer

Horizontal Mud Agitator

Constant Pressure Drilling Fluid Mud Gas Separator

Mud Gun

Mud Tank

Mud Tank Solids Control System Vacuum Degasser

Flare Ignition Device

Flare Ignition Device  Diesel Tank

Diesel Tank  Submersible Slurry Pump

Submersible Slurry Pump